Polypropylene (PP) spunbond non woven fabric ranks as one of the most widely used non woven materials across industries today. Non woven manufacturers in Hyderabad produce this fabric using advanced spunbond technology that ensures durability, versatility, and a broad range of applications. They melt polypropylene granules, convert them into strong and continuous filaments, and then bond them together to form high-quality fabric sheets. Companies like Savitridevi Polyfabrics, one of the trusted non woven manufacturers in Hyderabad, specialize in producing high-quality PP spunbond fabrics through a systematic, step-by-step process.

5 Steps of PP Spunbond Non-Woven Fabric Manufacturing Process

Step 1: Polymer Melting

The manufacturing journey begins with the melting of polypropylene polymer. The polymer granules are fed into an extruder, where they are heated to the right temperature until they reach a molten state. This molten polymer serves as the raw material for creating fine, continuous filaments. Proper control of the melting stage is critical, as it directly affects the strength and uniformity of the final fabric.

Step 2: Filament Extrusion

Once the polymer is melted, it is pushed through a device called a spinneret, which has very fine nozzles. These nozzles convert the molten polymer into long, thin filaments. As the filaments emerge, they are quickly cooled and solidified, ensuring they maintain their structural integrity. This step ensures that the filaments are strong enough to withstand the subsequent processes.

Step 3: Filament Laying

In this stage, the solidified filaments are randomly laid down onto a moving conveyor belt. The conveyor operates at a controlled speed, ensuring even distribution of fibers across the surface. The randomness of the filament placement creates a web-like structure that forms the base of the non woven fabric. Consistency during this phase plays a key role in achieving uniform fabric density.

Step 4: Bonding

The loose web of filaments must now be bonded together to form a cohesive sheet of fabric. There are three primary bonding techniques:

Thermal bonding: Heating the web so that fibers naturally fuse together.

Chemical bonding: Using a binding agent to join fibers.

Mechanical bonding: Employing mechanical means, such as needles, to interlock the fibers.

Most modern manufacturers, including Savitridevi Polyfabrics, use thermal bonding for its efficiency and strong results. This step gives the fabric its durability, texture, and final form.

Step 5: Finishing

In the final stage, the bonded fabric is processed into usable formats. It may be rolled onto spools for bulk use or cut into sheets for specific applications. Additional treatments, such as softening, printing, or coating, may also be applied depending on the intended use of the fabric. The finished PP spunbond non woven fabric is then ready for industries such as healthcare, agriculture, packaging, and hygiene products.

Quality Control at Savitridevi Polyfabrics

As one of the leading non woven manufacturers in Hyderabad, Savitridevi Polyfabrics ensures that every batch of fabric produced meets international quality standards. The company follows strict inspection and testing procedures, including:

Evaluating raw materials for purity and consistency.

Monitoring production at every stage for accuracy.

Performing chemical and physical tests on final products.

Maintaining full product traceability from raw material to delivery.

The PP spunbond non woven fabric manufacturing process involves five precise steps: polymer melting, filament extrusion, filament laying, bonding, and finishing. Each step contributes to producing a strong, reliable, and versatile non woven fabric. With rigorous quality checks and advanced production methods, Savitridevi Polyfabrics continues to stand out as one of the top non woven manufacturers in Hyderabad, delivering products trusted across industries.

Applications Across Industries

The versatility of non-wovens ensures their use in numerous industries:

Medical Sector: Surgical gowns, masks, bandages, and wound dressings.

Agriculture: UV-resistant crop covers, soil stabilization sheets, and pest protection fabrics.

Automotive: Upholstery, cabin filters, and acoustic insulation.

Home & Commercial Uses: Reusable shopping bags, furnishings, and filtration systems.

Their lightweight, durable, and cost-effective nature makes them indispensable in modern life.

Disposal of Nonwoven Fabrics

Once non-woven fabrics reach the end of their useful life, disposal becomes a critical issue. Since many non-wovens are made from synthetic polymers like polypropylene, they do not biodegrade easily. This creates challenges in terms of landfill accumulation and environmental pollution.

However, initiatives by companies like savitridevi polyfabrics are encouraging a shift toward responsible waste management and recycling practices. Being among the most innovative Non woven carry bags manufacturers in Hyderabad, they recognize the importance of closing the lifecycle loop.

Recycling of Non-Wovens

Recycling offers a sustainable solution for non-woven disposal. The process involves:

Collection: Used non-woven products, such as masks, bags, and filters, are collected.

Sorting and Cleaning: Materials are separated by type, washed, and dried.

Reprocessing: Non-woven waste is shredded and melted into pellets or re-fiberized.

Reapplication: These recycled fibers or pellets are reused to create new non-woven products.

Some non-wovens are also designed for biodegradability, using natural or compostable fibers to reduce long-term waste. Advances in recycling technology are making it possible to extend the lifecycle of non-wovens, minimizing their environmental impact.

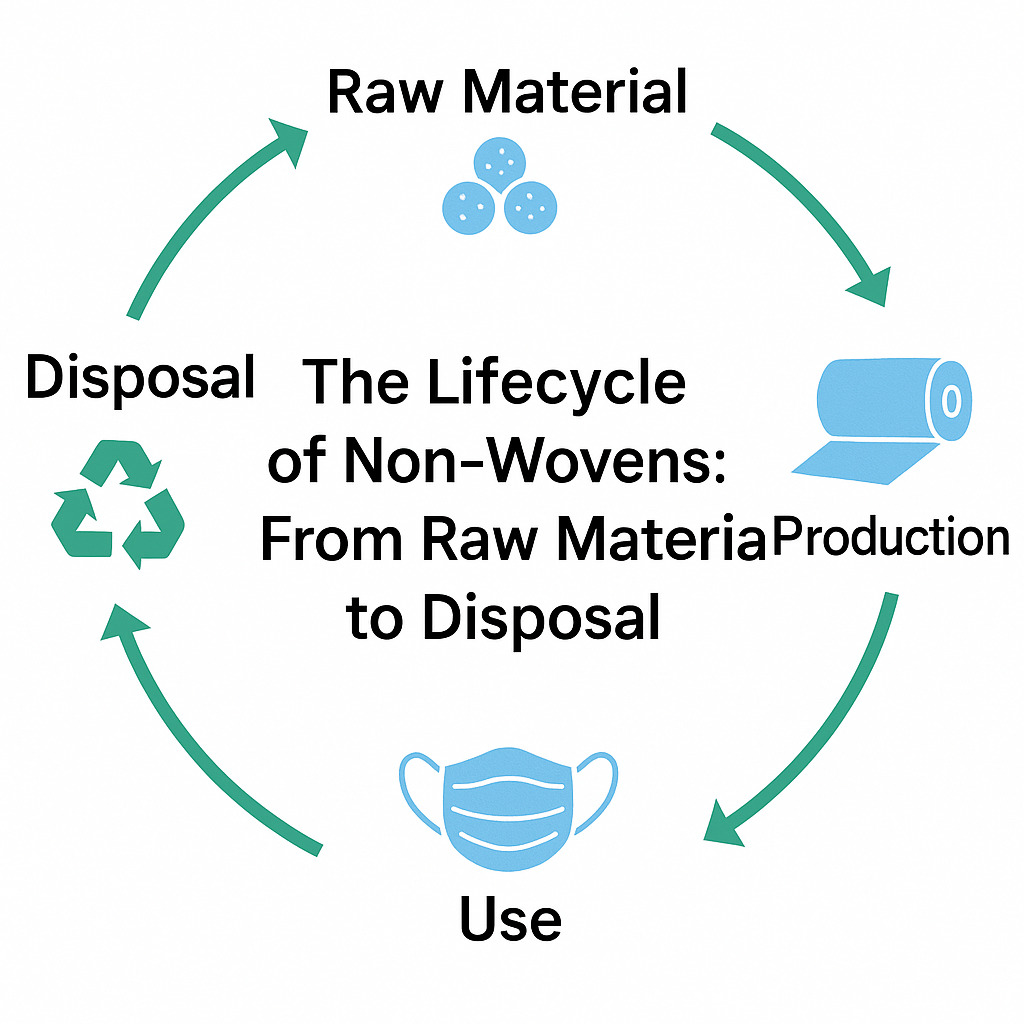

The Circular Economy of Non-Wovens

The future of non-wovens lies in adopting a circular economy model where materials are continuously reused rather than discarded. This involves designing fabrics with recyclability in mind, investing in technologies that make recycling more efficient, and encouraging consumers to reuse or return non-woven products. By embracing these practices, manufacturers can significantly reduce raw material consumption and minimize environmental pollution. Savitridevi polyfabrics, recognized as one of the top Non woven manufacturers in Hyderabad, is already leading in this direction by promoting recycling initiatives and sustainable sourcing.

Conclusion

The lifecycle of non-wovens from raw material preparation to recycling illustrates both their immense potential and environmental responsibility. These fabrics have transformed industries with their adaptability, strength, and affordability. Yet, their sustainability depends on how we manage their end-of-life stage.

With growing awareness and technological progress, recycling and reuse are becoming integral parts of the non-woven lifecycle. Manufacturers like savitridevi polyfabrics are showing leadership by embracing eco-friendly practices and providing innovative solutions. As one of the most reliable Non woven manufacturers in Hyderabad, they highlight how the industry can balance innovation with sustainability.

By understanding the lifecycle of non-wovens, we not only appreciate their role in our daily lives but also recognize the importance of responsible production and disposal. The future will belong to companies that prioritize both functionality and the environment, ensuring non-wovens remain a cornerstone of sustainable development.